A power tool that’s fixed in place and is not handheld or portable is classified as a stationary power tool. These types of tools tend to work quickly and accurately and usually operate via an electric motor. The most popular stationary power tools are explained here.

Table of Contents

Band Saw

- What it does: This default stationary power saw makes straight and curved cuts with a narrow blade that runs through a tilting table.

- What to buy: For the greatest versatility at a reasonable price, buy a 1- to 1 1/2-hp machine with a 14″ depth of cut and built-in light.

- Common accessories: Various blades ranging from coarse- to fine-cutting.

Belt/Disc Sander

- What it does: This tool combines a stationary belt sander on top with a stationary disc sander on the side to sand and shape wood boards and parts.

- What to buy: A 1-hp model with a 6″ × 48″ belt and a 12″ disc.

- Common accessories: Replacement belts and discs in grits ranging from coarse to fine.

1” Belt Sander

- What it does: On this machine, a vertically mounted abrasive belt moves through a tilting table, and a vertically mounted 4–8″ disc spins on the side. This tool removes stock from wood parts and sharpens metal edges on tools such as chisels, axes, shovels, and pruning shears.

- What to buy: A 1/2-hp tool with a 1″ × 30″ belt, a 4–8″ disc, tilting tables, and a dust collection port.

- Common accessories: Abrasive belts and discs in grits ranging from coarse to fine.

Bench Grinder

- What it does: Sharpens tools ranging from chisels to lawn mower blades.

- What to buy: A 1/2-hp model with two 6″ diameter wheels, clear plastic spark shields, and a built-in light.

- Common accessories: Various replacement wheels with grits ranging from coarse to fine.

Chop Saw

img: kljack.com

- What it does: Also called a power miter box, this table-mounted, up-and-down-pivoting saw makes square and angled cuts in wood boards. It’s used primarily for cutting boards to length and cutting miters on molding boards.

- What to buy: A model with a 10-amp motor, 10″ blade, automatic blade brake, and dust collection bag.

- Common accessories: Various replacement blades and auxiliary fence parts that make supporting and holding stock easier.

Drill Press

- What it does: This tool is nothing more than a drill head that moves up and down against a heavy-duty table. It’s used to bore accurate holes in wood and metal and to sand curved edges onto wood parts.

- What to buy: A unit with a variable-speed 1-hp motor, a 5/8″ chuck, and a tilting table.

- Common accessories: Various drill and spade bits and sanding drums.

Stationary Jigsaw

- What it does: Also called a scroll saw, this tool has a short, narrow blade that moves up and down through a tilting table. It makes fine, curved cuts in wood, metal, and plastic.

- What to buy: A unit with a 2-amp, variable-speed motor that produces 400–1,600 strokes per minute; a tilting table; and a built-in light.

- Common accessories: Various replacement blades.

Jointer

- What it does: This stationary machine has two heavy tables—one in-feed and one out-feed—with a horizontal rotary cutter mounted between them. It removes stock to flatten the edges and surfaces of solid wood boards before they’re joined.

- What to buy: A 2-hp model with a 6″-wide cutter, a tilting fence, and a dust collection port.

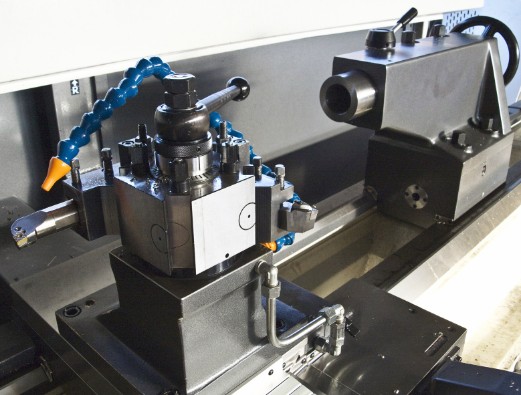

Lathe

- What it does: Holds wood parts horizontally between a headstock and a tailstock. Its motor turns wood blanks and cuts them with chisels to form round parts, such as stair spindles, lamp bodies, and wooden bowls.

- What to buy: A 1- to 2-hp, variable speed motor with 5″ clearance between the headstock and the table and 36″ between the headstock and the tailstock.

- Common accessories: Various replacement stocks, drill chucks, and faceplates for mounting larger wood blanks.

Planer

View this post on Instagram

- What it does: This tool has a horizontally aligned rotary cutting head mounted above a sturdy table. When a wood board is passed between the cutter and the table, the machine removes stock from the full width of the surface in one continuous pass, leaving a smooth board of uniform thickness.

- What to buy: A 12″-wide machine with a 15-amp motor, a 1/8″ depth of cut, and a dust collection port for attaching a vacuum.

- Common accessories: None

Radial Arm Saw

img: thesprucecrafts.com

- What it does: Essentially a portable circular saw mounted on a moveable arm over a stationary table, it makes crosscuts, rip cuts, and angled and mitered cuts by moving the arm and saw into different positions.

- What to buy: A unit with a 10″ saw blade, a 1 1/2–hp motor, a blade brake, and a sawdust vacuum port.

- Common accessories: Various replacement blades for cutting a wide range of wood and manufactured panels.

Table Saw

View this post on Instagram

- What it does: This tool has a tilting blade that’s mounted in a large table, outfitted with an alignment fence. It cuts boards and panels across their width and length and at any angle.

- What to buy: A unit with a 1 1/2–hp motor and a 10″ blade that can tilt to at least 45°. The attached table should measure at least 2′ square.

- Common accessories: Various blades for cutting different woods and manufactured panels.